Digital future of contractor management

For social and economic development of any country, managing contracts plays a critical role.

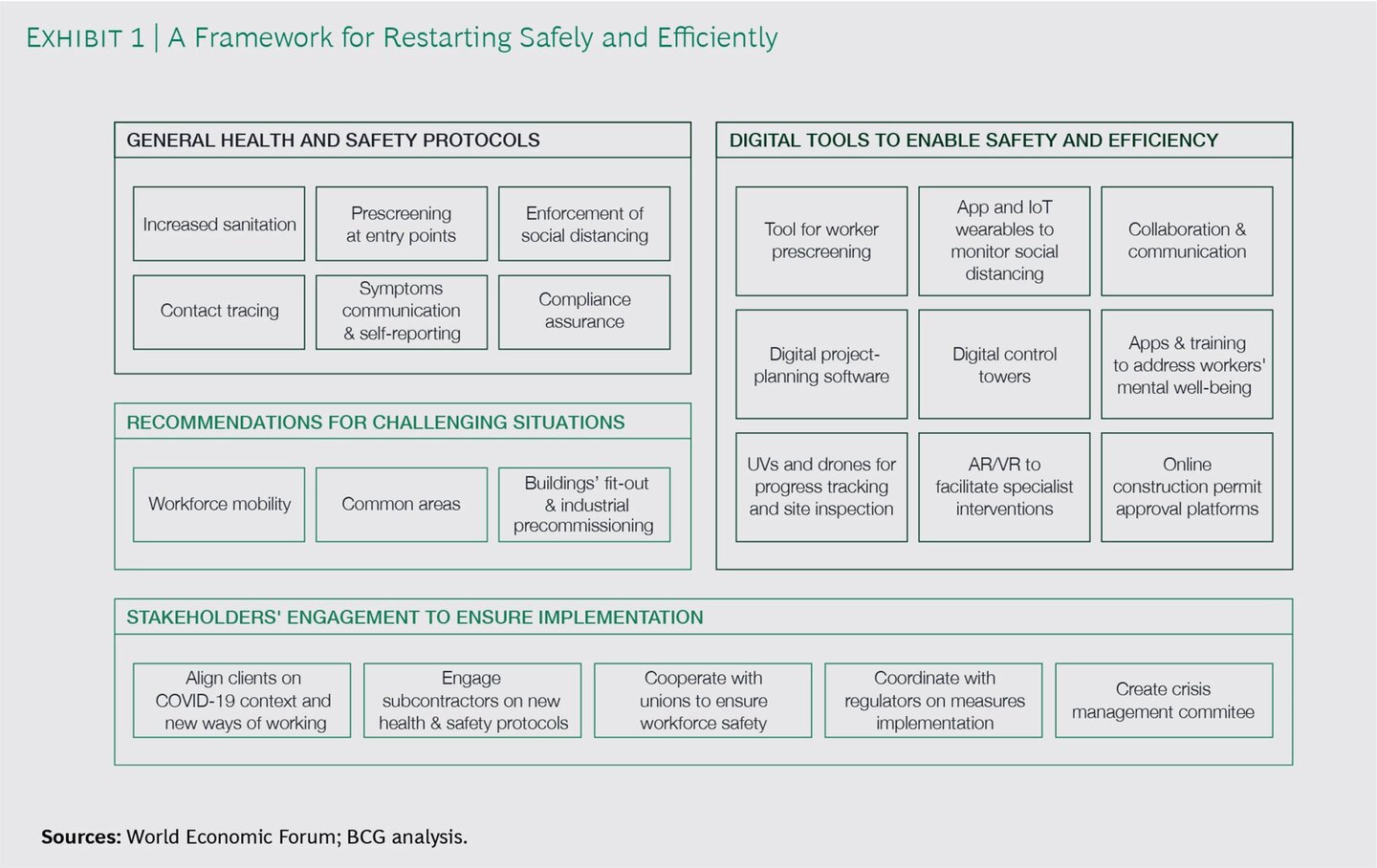

While dealing with inherent particularities such as human interaction, space limitations and the physical nature of the work, BCG states that industrial sectors should have –

- Health and safety protocols and guidelines to carry out construction activities

- Measures to overcome specific challenges

- Digital technologies to enable a safe and efficient working environment

- Coordination among stakeholders to ensure an effective implementation of the proposed actions.

It even states a framework for restarting operations safely and efficiently – which is given below.

But, to roll out solutions across sites that involve contractors and their teams across geographically dispersed locations is no easy task – compare an oil industry with a construction one. Plus with varying sophistication levels that function in hierarchies as subcontractors, building newer capabilities at scale is another challenge.

The growing demand for construction and coordinated approaches means traditional practices must change. Large construction sectors have tried to focus on making incremental improvements, but that too in parts because each project is unique – scaling up new ideas suddenly and embracing them is impractical from the industry professionals’ point of view.

In large industries that involve involvement of a huge workforce and ongoing onsite work, project planning remains uncoordinated between the office and the field – often the tasks are executed on paper.

One reason for poor productivity records is the reliance on paper to manage processes and their deliverables such as equipment logs, supply chain orders, design drawings, daily progress reports, blueprints and punch lists. Paper usage makes difficult to capture and analyze data – the most crucial factor in procurement and contracting. Since digitization hasn’t taken firm roots yet in managing contractors and their workforce, information sharing is delayed and isn’t made universal and transparent. Further lacks historical performance analytics and proper risk management.

Mismanaged paper trails can routinely spur disagreements between owners and contractors on issues such as construction progress, change orders, and managing claims.

The most severe implications that stand out are: project delays, productivity losses and disruptions in the supply chains. Additional management challenges have taken roots – employees (contractors and workers both) are experiencing toxic levels of stress, leading to secondary wave burnouts and stress-related absenteeism.

After the period of activity stoppage, construction activities have started but compliance needs to be ensured by recurrent onsite inspections.

Current conditions create a test field to foster the adoption of digital technologies and limit human interaction and the time spent at sites and continue building collaboration.

Digitizing safety processes is moving away from paper towards online, real-time information sharing to ensure transparency and collaboration, timely progress, proper risk assessments, quality control, and, better, more reliable outcomes.

Digital project planning software such as Contractor Management Software, apps and training to address mental wellbeing of employees, online construction permit approval platforms engage subcontractors on new health and safety protocols and ensure workforce safety.

The execution requires interest and seriousness in safety since implementation needs thoughtful engagement and cooperation among multiple stakeholders. An effective digital supply chain backbone ensures smooth and on-time transportation of materials from factory to site to use. Because resisting such changes is now no longer an option.