Managing Occupational Safety and Health Risks in Oil & Gas Industry

Safety and health management is one of the indispensable components of Oil and Gas industry because the lion’s share of the functional conditions like chemicals and outputs associated with Oil and Gas production pose prominent serious safety and health threats to the workers who are part of the project.

The Oil & Gas industry involves high-risk activities which are limited not only to exploration but also production and processing of highly flammable & explosive materials. This industry requires heavy / complicated / expensive machinery, massive manpower and an extensive support system. Additionally, it requires high investment and has a long payback period. In terms of geography, this industry being strategic and vital, is situated in remote locations and may have its own challenges. In case of any accident consequences, it could be catastrophic, in terms of several casualties, environmental pollution etc, which can result in damaging the reputation of an organization as well.

Hazard Identification & Risk Assessment

A Hazard is any source having the potential to harm, damage, or adverse health effects or property loss under a certain condition at work. Risk is the combination of severity and likelihood of a Hazardous event that might have occurred. Hazard Identification and Risk Assessment is a process to identify Hazards, analyse or evaluate the Risk associated with that Hazard, and determine appropriate ways to eliminate or control the Hazard. It is a process to identify those conditions, situations, processes, etc that may cause harm. Once it is identified, evaluate how likely and severe the risk is, and then decide what are the control measures to be put in place to prevent or control the harm from happening.

Each activity may have a different Hazard and its respective control method. The control measure for each Hazard is to be applied so that the Hazard level can be reduced to as low as reasonably practicable. Normally all control methods are used during fieldwork.

Let us get to know more about Oil & Gas Industry Hazards –

Oil & Gas Industry Hazards

- High- pressure Oil or Gas from the reservoir, inside pipes & vessels, high- pressure steam from the boiler are considered Pressure Hazards

- The High Temperature at compressor discharge pipe and low temperature at liquid nitrogen tank are considered Temperature Hazards

- Rotating equipment, drill pipes, rotating motor shaft, swing object during lifting and shifting activity are considered Motion Hazards

- Corrosion inhibitor and lube oil are Chemical Hazards

- Lightning, electrical work, power supply to Heater are considered Electrical Hazards

- Slip, trip, fall, falling object, heavy lifting, and shifting are considered Gravity Hazards

- High noise of compressor / Diesel Generator (DG) is considered Noise Hazards

- Toxic gas release from vent and safety relief valve creates Hazardous atmosphere

- Work inside pressure vessel is considered Confined Space Hazards

- Laying buried pipe, cables, etc. is considered Excavation Hazards

- Working with a grinding machine is considered Sharp Object Hazards

- Scaffolding work above the sea and subsea pipeline inspection are considered Water & Underwater Hazards respectively

- Welding inspection radiography by X-ray is considered Radioactive Hazards

- The Wrong position during manual lifting and shifting is considered Manual Handling Hazards

We are still reeling in shock from Vizag Gas Leak, an industrial accident that occurred at the LG Polymers chemical plant in the R. R. Venkatapuram village of the Gopalapatnam neighbourhood, located at the outskirts of Visakhapatnam, Andhra Pradesh, India, on 7thMay 2020. As per the National Disaster Response Force (NDRF), the death toll was 11, and more than 1,000 people became sick after being exposed to the gas.

Preliminary investigations concluded that the accident was likely the result of insufficient maintenance of units storing the styrene monomer, improper storage, and operation errors.

Safety is becoming of paramount importance to eliminate the risk associated with Oil & Gas Industry

Now let’s know the ways of controlling Oil & Gas Hazards –

Controlling Oil & Gas Hazards

For Oil and Gas Industry, Hazard elimination is almost impossible in most cases as Oil &Gas Industry has been considered a High-Risk Industry. There are two types of Safety Engineering – one is Process Safety and the other is Occupational Safety. Process safety focuses on preventing fires, explosions, and accidental chemical releases in process facilities.

Occupational Safety & Health focuses on Personal Safety. Safety at Oil & Gas also focuses on specific procedures, guidelines, and the Permit to Work system. PPE (Personal Protective Equipment) is to be considered as the last protection to humans. Certain jobs need special PPE in addition to standard PPE. For example, a welding job requires a special welding mask and not just safety glasses.

Specialized Trade-specific Training is for personnel working in a dangerous location like the Oil &Gas industry and is to be conducted periodically

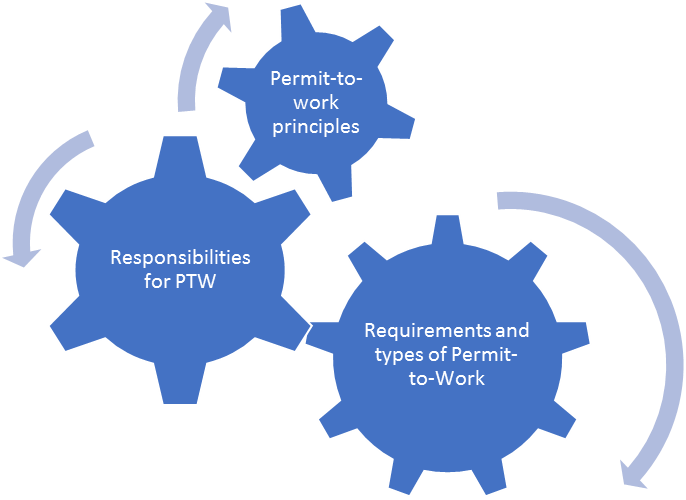

In Oil & Gas Industry, the Work Permit system is used to control High-Risk activities. This system includes assessment of Risk and specifies control measures to be in place to minimize the risk at the workplace. Permit to Work system to be evaluated by concerned head of Safety and Head of Operation and to be approved by Plant Head.

ASK-EHS conducts Permit to Work Safety (PTW) Training on-site as well as on-line as per client’s requirements on a regular basis.

The permit to work Safety Training Module

ASK-EHS also facilitates a wide range of Hazard Identification and Risk Assessment workshops (e.g. HEMP, HAZOP, HAZID, LOPA, SIMOPS, and Bow-Ties).

Contact us to know more.