Effective Safety Culture: Key to eliminating accidents in Steel Plants

Steel is the most ordinarily used metal in the world. It’s everywhere in our life. Steel isn’t one product, but there are over 3500 different grades of steel with various physical, Chemical, and Environmental Properties, allowing a spread of thickness and shapes. Each grade of steel has properties designed for specific applications.

Over 75% of 3500 steel grades in use today, failed to exist 20 years ago.

Let’s understand the steel industry on World Steel Day.

In fact, production was a hazardous process and mishaps were inescapable. Today, many steel companies recognize that this is often now, not appropriate for a contemporary and technically advanced industry.

Every Steel industry is committed to maintaining a secure and healthy workplace and working on safety and health incidents, risks, and opportunities for improvement. They consider safety and health to be an integral component of doing business, and it starts with each people.

Every industry believes that the protection and health of people should underlie value and must not be compromised in the face of other business challenges. This applies to everyone involved within the industry, including business leaders, employees, contractors, and other third parties like suppliers, customers, and visitors.

The world steel association provides certain guidelines and standards for the steel industry’s approach to safety and health.

Its main purpose is to create it clear that the industry is committed to maintaining a secure and healthy workplace and needs to stay engaged in safety and health incidents, risks, and opportunities for improvement.

World steel association encourages all steel companies to use principles and metrics in their organization and set standards for the industry.

Six safety and health principles for the industry

- All injuries and work-related illnesses can and must be prevented.

- Managers are responsible and in control of safety and health performance.

- Employee Engagement and training is essential.

- Working safely may be a mandatory condition of employment.

- Excellence in health and safety drives excellent business results.

- Safety and health must be integrated into all business management processes.

These principles lay the idea of a perfect safety culture for any organization. Safety culture is the collection of the beliefs, perceptions, and values that employees share in reference to risks within a corporation, like a workplace or community.

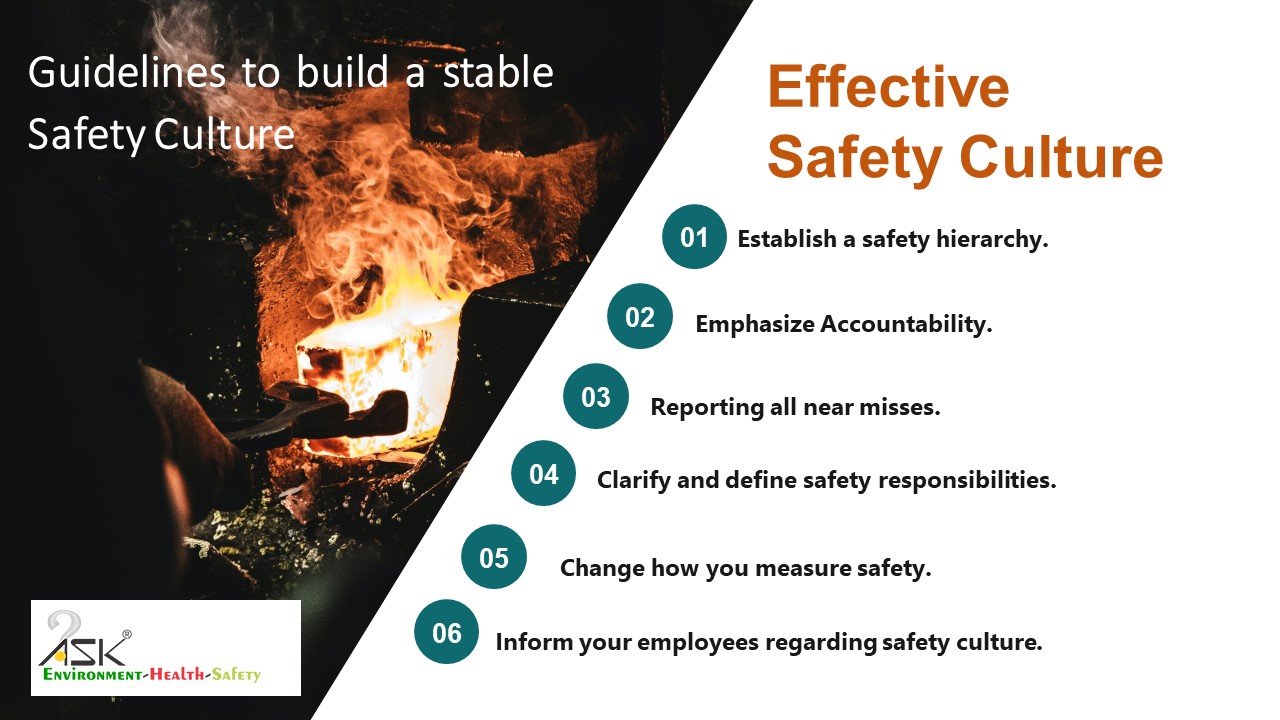

Tips to assist and create a good Safety Culture

Developing and retaining a thriving safety culture is an evolving process that needs dedication from the complete workforce of a company.

General efforts deliver outcomes that include an optimistic outlook regarding safety and a reduced number of incidents and accidents.

Some Amazing Facts about STEEL

- When Iron is combined with carbon, recycled steel, and little amounts of other elements, it’s transformed into a far stronger to other elements. It’s transformed into a far stronger material called steel, employed in an enormous range of human-made applications. Steel will be 1000 times stronger than iron.

- Steel is an alloy of iron and carbon-containing but 2% carbon manganese and a tiny low amount of silicon, Phosphorus, sulfur, and oxygen. stainless-steel may be a steel alloy with a minimum of 10.5% chromium content by mass.

- When liquid iron is converted into steel it reaches temperatures of up to 17000 Celsius, significantly hotter than volcanic lava.

- In the 3rd century BC, craftsmen in southern India were using crucibles to smelt atomic number 26 with charcoal to provide WOOTZ steel- a fabric that’s still admired today for its quality.

- All Steel is originally made up of IRON. Iron is the 4th commonest element within the earth’s crust after oxygen (46%), Silicon (28%), and Aluminum (8%).

How ASK-EHS can help?

ASK-EHS can help the industry assess its current safety and risk management maturity across their organization, and accordingly determine appropriate focus, process, and technology practices.

We evaluate organizational safety culture & re-engineer it for reaching safety standards &the necessary benchmarks. We concentrate on provisioning a paradigm shift in an organization’s safety culture and reworking it into a security champion.

We’ve proudly served over 1 million users in 600+ customers spread across 30+ different countries worldwide. Our efforts are recognized and rewarded through prestigious awards and renowned felicitations, making us the well-liked choice for implementing safety management systems.