Data driven safety decision-making

The insights that matter most to businesses today are often hidden behind processes and ‘systems’. The combined knowledge and data hidden within the realms of these two have led to a conundrum – far and few are aware of ‘how’ to unlock business insights from within them.

Insights like access to key performance indicators, baseline readings related to business processes and indicators that reflect the health of safety systems.

In this pursuit of refining and automation, cognitive biases play a significant amount of role, as to what a trained supervisor and manager will choose: Response or React.

This has a profound effect on safety decision-making.

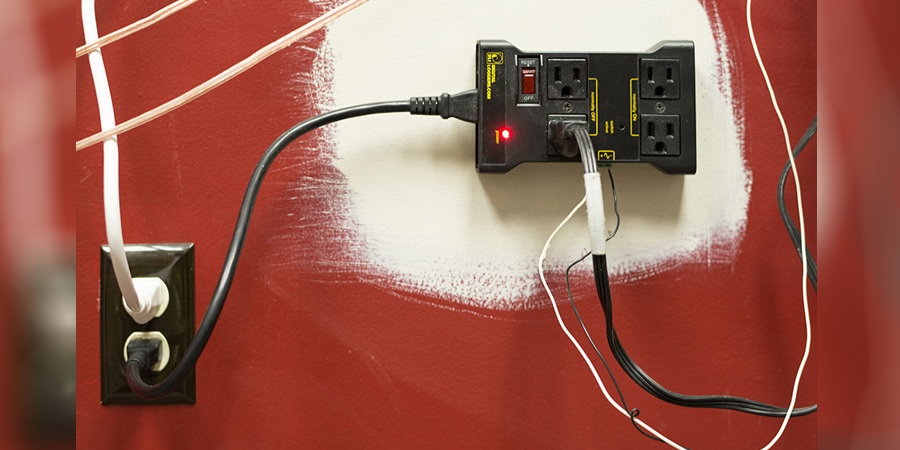

For example, a process safety driven organics manufacturer might not want to hotwire and connect his newly commissioned equipment to the safety management software.

The logic: Native data can create artifacts within the system which might not look good for the reporting.

The problem: How else would we know, as to how integration of newer systems and equipment makes the safety management software behave, hotwiring from the word ‘go’ seems better.

The solution: Isolating data responses and interactions within a customized flow for better reception, processing and secondary vigilance by the safety team.

However, with the corollary comes the burden of finding such efficient systems which can allow for flexible monitoring and secondary vigilance. Most EHS management software with their dedicated workflows and function do not allow for such dexterity.

Getting bespoke software engines developed seems like a higher cost proposition, but that is in fact, a misnomer.

Customised EHS software allow businesses and organizations to create data pivots based on their work environment. These so called data pivots are nothing but smaller built-in data ‘flows and interactions’ that can be measured. Measured as per industry prescribed standards and be moulded into what organizations call, standard procedures. Custom flow also allows for lesser training and integration time for employees, even at remote and off-shore worksite. The key here being, familiar workflows emulated by EHS software, allows for better memory via recall.

Software technology has its deliverable efficiencies, but what do businesses forget about – “core efficiency”, that it needs to be understood by software companies. These are based on the business intelligence and model which surrounds the entire organizations. Software companies need to transform these into the heart of their EHS software and then deliver it to the said client.

Off-the-shelf software motivation in today’s rapidly evolving business philosophy finds little heart. Constant investment is the biggest challenge in this regard.

But, customized software can weather the storm with purpose built processes which replicate on-ground operations for the workers to gauge and learn from. The excel table and word documents are all integrated cleverly while the core reporting and data entry interfaces with mobile forms become readily accessible to all.

Safety decision-making relies on these strengths and agility. Who said that the agile model is only for businesses, EHS software can learn quite a few tricks from it as well.