Outsourcing to reliable Safety partners?

In this day and age it is not a shocking question anymore. “Safety” or the all-encompassing aspects of EHS and OHS – outsourced to a safety partner.

Does it work, is it reliable or is there more to it than meets the eye?

Curiously, safety allows to blends both behaviour, engineering and management than most applied disciplines – how can one be sure, how to go about, outsourcing safety?

The answer is simple – safety has a characteristic trait that lets you identify itself from other so called “safe” practices i.e. its proactive nature.

When this is combined with the human element at workplace, we get occupational health and safety, all the while environmental component is referred to as Environment, health and safety.

Coming back to our original debate on outsourcing safety, these two components of being proactive, while preserving the human elements is necessary to safety. Outsourcing can happen in many different forms and ways:

– Trainings are the most direct way to impact your workforce.

– Manpower for all the different levels within the organization

– Software modules that allow an organization to transform, digitally.

And many such avenues exits where, in one way or the other a company lets the safety components be adjusted and tinkered by an outsourcing agency. This is the modern day reality of building things as we go, of-the-shelf competencies that are wielded as will.

The challenge for organizations is how to ensure the right standards and enforce best practices when outsourcing for ‘safety’.

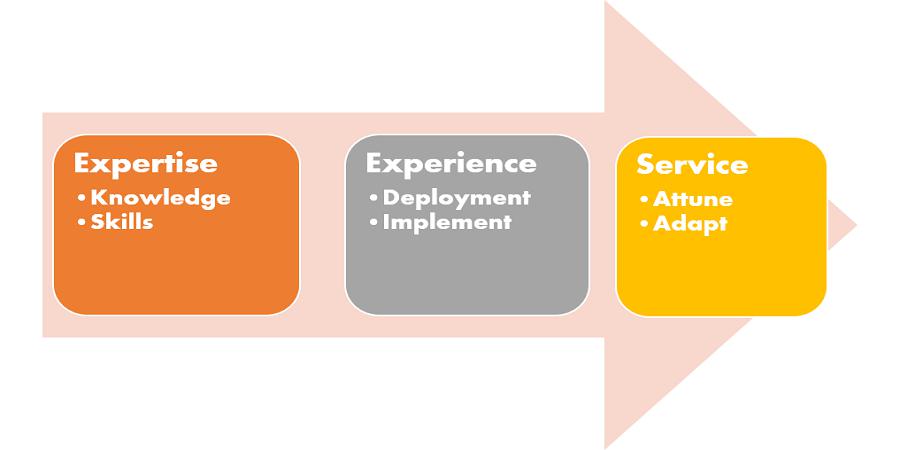

This is a non-binding but broadly used timeline of how an ‘outsourcing for safety’ model works. The professionals not only need to show their expertise via knowledge and skill based craft but then need to deploy and adapt it according to the requirements of an ever-changing site, company or factory.

The regulations can change but good service models allow for such changes to be attuned within the EHS or OHS regimen – via tools such as change management and employing better learning aids like animation and e-Learning.

Safety cannot be limited by stringent criteria that can stand to harm the integrity of operations. Outsourcing can alleviate this problem by bringing in ready-to-deploy competencies that have been previously tested out in the market. Their work reports, references and audits can vet there credentials, meanwhile, if there is simply a case of plugging known manpower gaps, then trained and certified manpower are available.

Growing comfortable in such a service model might seem like a challenge and yet due to the interconnectedness within OHS and EHS domains, a lot of such challenges overlap, and therefore, overcome practical hurdles.

More importantly, outsourcing to experts can lend an extra pair of ‘eyes and ears’ to the on-ground safety team – this not only ensures vigilance but provides confidence to safety officers that can mutually rely on their counterparts to do the right thing.

Reactive safety might be considered in pale light than the shine of proactive safety but it must be understood that some of the most hazardous workplaces (cement kilns, oil and gas rigs and chemical plants) actively depend on their employee’s overall involvement and reaction to unknown hazards. Outsourcing safety can enhance such traits for the best.