Reducing construction injuries – Key solutions

Injuries and construction sector are bonded together through their work relationship. At least that is what the accident-incident data reflects from different regions across the world. The construction sector remains one among the most occupational safety and health hazards prone domain than others.

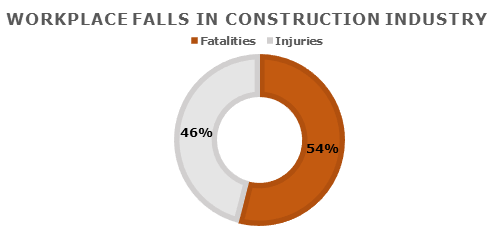

The main culprits apart from the hazardous nature of the work, are the work culture, attitude towards safety and lack of transparency. A case in point is represented below which suggests that 54% of fall victims for 33 years (1982-2015) succumbed due to non-availability of personal fall arrest systems, at construction sites.

Data sourced from NIOSH FACE Reports

The Usual Suspects

Leading causes of workplace injuries in construction sector remain:

- Falls

- Struck by objects

- Electrocution

- Caught between objects

There are myriad reasons from operational, EHS and competence viewpoint that act as a barrier between the construction project site and their safe work operations. Some of the factors which continue to be central to the success of injury-free work in construction sector versus the challenges they face have been provided1 are;

- Maturity in plan preparation Vs Selection of contractors and talent shortages.

- Maturity in risk control and governance Vs Lack of project management information systems (PMIS)

- Maturity in performance Vs Lack of consistent approach for contingency

Such analyses of pitting the frequent and known issues against the maturity of control, presents a more tangible purview of an evergreen problem within construction sector. Construction injuries will continue to rise if risk management, contingency planning and above all, a well-defined EHS plan aren’t integrated within the project planning and management.

Key Solutions

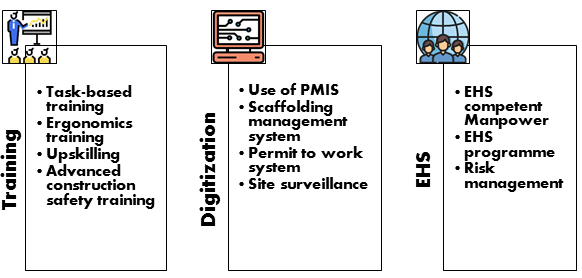

Here are the key solution which can help tackle and reduce the construction sector injury rate and overall fatalities. Training in the form of job-specific programs can sharpen the grasp of the manpower at construction site. Such trainings help the workers to adjudge and execute safe works whether working at height or undertaking rigging and lifting operations. Broader trainings such as ergonomics and advanced construction safety are meant to increase the work environment awareness-response. Safety is inculcated via practice with repetition and these training modules along with upskilling provide the commensurate practical education to enable safety.

Training in the form of job-specific programs can sharpen the grasp of the manpower at construction site. Such trainings help the workers to adjudge and execute safe works whether working at height or undertaking rigging and lifting operations. Broader trainings such as ergonomics and advanced construction safety are meant to increase the work environment awareness-response. Safety is inculcated via practice with repetition and these training modules along with upskilling provide the commensurate practical education to enable safety.

Digitization is the progressive trend and project management information systems facilitate necessary information distribution. Construction sites with tight work deadlines along with the stringent need of well-organized resource management can gain tremendously from scaffolding management. Prevention of injuries lies at the heart of a digitally enabled permit to work system. Digitization brings the cognizance of advanced safety controls to the construction sector.

EHS manpower at your construction worksite is the need of the hour. They provide the degree of reliability with the assured delivery of work, all within the safety net of EHS accredited operations. The talent shortages that somewhat cripple modern construction worksites are easily dealt with qualified EHS manpower that are suitably trained and who propagate safe working practices. Construction injuries in majority cases are dependent on human behavior. It’s role in determining what is safe or unsafe plays an important role in developing demonstrated behavior or as we commonly refer to – habits.

Safe habits should take precedence over unsafe ones but poor judgement, questionable practices for time saving and lack of guidance setback construction work practices.

Emerging trends suggest employing behavior based safety observations and tracking them on digital platforms can be useful. Recently, large to mega-scale construction projects have started deploying surveillance drones. The primary purpose of these drones is to survey and map the entire operations. On secondary note, such remote controlled eye-in-the-sky can monitor and determine unsafe conditions for certain types of work such as lifting operations by crane on poor ground conditions.

On that note, here is a statistic from the Global Construction Surveys 2017 by KPMG International which documents that 83% of its respondents are yet to implement a “robotics process automation/digital labour” operation. While 76% further added that it would take another 5 years to fully integrate such a system. The case for digitization and modern training methods writes for itself.

References

1) KPMG International, Global construction surveys 2015.

2) KPMG International, Global construction surveys 2017.

3) WEF, Shaping the future of construction Insights to redesign the industry, March 2017 (Whitepaper).