Digital QHSE for Modern Workplace

Operational excellence as an industrial target has myriad objectives that are anchored within the basic activities and behaviour – driven and defined by the industrial stream. Holistically, we can perceive this as a value stream ‘management approach’ that allows to see the flow of value to the business as well as the customer.

It also identifies and devises ways and means to avoid breakdowns, incidents or non-conformance(s). Digital frameworks built at-heart as ‘safety software’ can enable modern industrial world to ingrain quality as a competency – all within the EHS and OHS realm.

From our last blog, it is evident that QHSE incorporates elements of Quality and EHS systems to streamline operations and helps maximize ROI, and for industries, this is need of the hour.

Good software tools can provide solutions to challenges through flexible control and distribution of data within a collaborative environment.

Standardized systems for efficiency and reliability

Without access to quality data, it is tough for the managers to take their best decisions about safety and risk strategies, equipment resources, which projects to develop etc. Lack of all these can lead to increased operational risks.

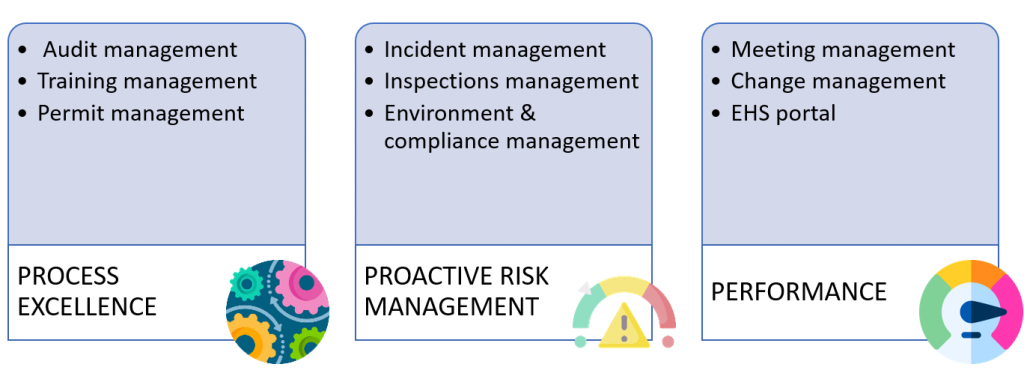

Take internal audits and trainings. Both of them are a regular affair in industries – their frequency and efficiency needs to be monitored as well. In case of trainings, a management software can help plan, schedule, assign and track learnings. With each employee’s training portfolio, an accurate need-gap analysis helps in determining the quality of resources in the organization.

Monitoring one’s workplace, resources, equipment is essential to track discrepancies. For EHS, this includes incidents, inspection, change management and audits. For QMS, this constitutes operations, non-conformances and maintenance. Plus, the records of incidents and inspections benefit while conducting a risk management.

Similarly, managing permits is a compliance requirement, and their ‘know-how’ through a digitized approach improves ‘escalation management’ in industrial operations. It addresses the uncertainties in the daily processes and helps control risks at all stages.

These software tools help investigate, evaluate and maintain systems, properly manage processes – through them, industry professionals gain insights into how issues overlap and mesh together.

Tools to integrate personnel

Digital management allows the users to focus on key components of a business, save time and attend critical EHS initiatives. Software tools can schedule meetings, roles, agendas, topics and responsibilities, thus coordinating all of it especially when employees are spread out in different departments, shifts, and facilities.

Digital portals ease the spread of complaints and issues – provides a platform for all the workers to express their ideas and their opinions, good practices, thus facilitating worker engagement.

Quality and EHS are no different – without a core business intelligence and reporting functions, it becomes a challenge to understand the various trends and data points in the regular happenings. QHSE can uncover a whole new layer of data analysis, one that takes into account not only the quality of a product (or process), but also the associated EHS impacts.