Why is Hydrogen Sulfide listed in the Major Accident Hazard (MAH) category for Hydrocarbon operations?

H2S is identified as Major Accident Hazard (MAH) in Hydrocarbon operations. Each day, many workers in the oil and Gas, petrochemical, construction, wastewater, paper-pulp and other industries are exposed to hydrogen sulfide gas. Hydrogen Sulfide is a colorless, transparent gas with a characteristic of a rotten-egg odor at low concentrations and not detectable by odor at high concentrations. Hydrogen sulfide is the chemical compound with the formula H2S.

It is highly flammable and toxic, even at low concentrations. HMIS (Hazardous Materials Identification System) and NFPA (National Fire Protection Association) gave H2S a flammability rating of 4, which is the highest rating. It is heavier than air and may travel along the ground. It can build up in low-lying areas, and in confined spaces (including enclosed, poorly ventilated areas). After a while at low or more quickly at high concentrations, you can no longer smell it to warn you it’s there. It can quickly, almost immediately, overcome unprepared workers, including rescue workers.

Characteristics of Hydrogen Sulfide

- H2S is very poisonous, corrosive

- People can smell the “rotten egg” odor of hydrogen sulfide at low concentrations in air.

- If gaseous hydrogen sulfide is put into contact with concentrated nitric acid, it explodes.

- It may travel to sources of ignition and flashback.

If ignited, the gas burns to produce toxic vapors and gases, such as sulfur dioxide (SO2). Contact with liquid hydrogen sulfide causes Frostbite. If clothing becomes wet with the liquid, avoid ignition sources, remove the clothing and isolate it in a safe area to allow the liquid to evaporate.

H2S in workplaces – Hydrocarbon operations

Hydrogen sulfide is produced naturally from decaying organic matter. It can be released from sewage sludge, liquid manure, and sulfur hot springs, and with natural gas. It is also used or is a by-product in many industrial processes such as:

• The petroleum industry, especially at oil and natural gas wells; in refineries, where H2S is removed from natural gas and oil; and in pipelines used to carry unrefined petroleum.

• The construction industry, where H2S could be released during excavation work in swamps or old landfills.

• Sewers, sewage treatment plants, manure tanks, and other places where organic material breaks down without oxygen (Confined spaces).

• Iron smelters, coke ovens, and other places where H2S may be a by-product.

• In some mines and tunnels where mineral rock may contain H2S.

Even at lower concentrations, H2S has the potential of causing major damages to human life & limb. At higher concentrations, it kills silently and instantly. With the advent of growing natural gas exploration, the risk of being exposed to it has increased greatly. Active monitoring for hydrogen sulfide gas, good planning and H2S training and awareness programs for workers are the best ways to prevent injury and death.

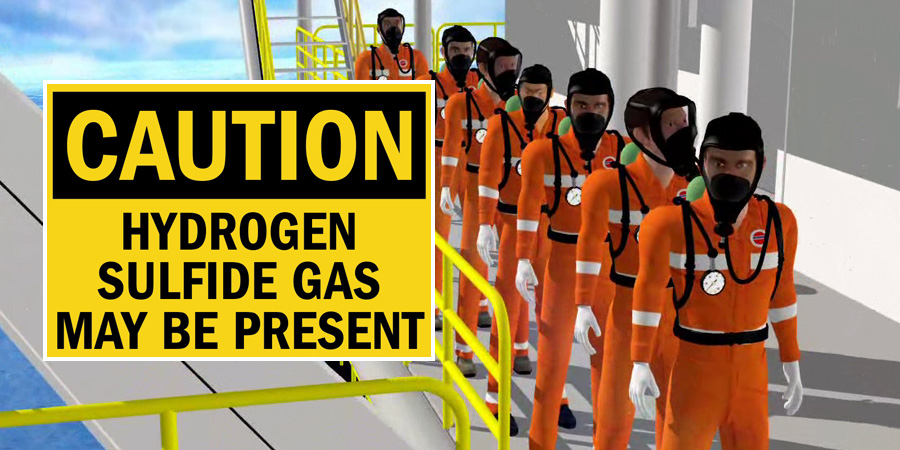

ASK-EHS is an organization with a vision to support workplace safety initiatives of global corporations. Our products and services are designed to support this vision. The first “over-the-counter” product – H2S, a 3D animated H2S training & awareness program, is launched to prevent injury and death at work place.

3D animated H2S training and awareness program consist of 5 different modules like:

• Introduction to Hydrogen Sulfide (H2S).

• Properties and characteristic of H2S.

• Introduction to Hydrogen Sulfide (H2S).

• Effects of exposure to hydrogen sulfide and exposure limits.

• H2S detectors, respiratory equipments and their uses.

• Emergency Procedure.

These modules will help organization to train their workforce by showing them H2S safety videos. It is necessary for every organization that are exposed to H2S to provide hydrogen sulfide safety training. Hydrogen sulfide safety training programs need to be conducted in every 3 months, so easy way for organization to promote training is by showing hydrogen sulfide movies or H2S safety video to their work force. Does H2S pose a serious threat in your operations? Know more on how you can reduce the risk significantly by showing H2S safety video at – /

References:

•Hydrogen_sulfide

• hydrogensulfide

Beside Hydro carbon industry, Hydrogen sulfide gas is also responsible for multiple sewer-worker’s death syndrome.Multiple deaths have occurred worldwide since the first waste water sewers were built due to the anaerobic conditions prevailing in the sewar line resulting in the formation of H2S gas. It starts with worker going one by one while working in a sewer line and suddenly getting collapse. Earlier,It was believed that sewer deaths were due to a lack of oxygen before the toxicity of hydrogen sulfide came to focus. Hydrogen sulfide gas in an oxygen rich environment can be more dangerours and explosive when ignited, thus adding to the danger

Crude oil containing high sulphur content when processed in refineries will generate hydrogen sulphide with emphasis in hydroprocessing scheme or sweetining schemeto control sulphur acording to theinternation product spec for each product. The huge quantities of hydrogen sulphide generated is used for production of elemental sulfur.

Hydrogen Sulfide (H2S)

Hydrogen sulfide is a colorless, flammable, extremely hazardous gas with a “rotten egg” smell. It occurs naturally in crude petroleum and natural gas, and can be produced by the breakdown of organic matter and human/ animal wastes (e.g., sewage). It is heavier than air and can collect in low-lying and enclosed, poorly ventilated areas such as basements, manholes, sewer lines and underground telephone/electrical vaults.

Detection by Smell

Can be smelled at low levels, but with continuous lowlevel exposure or at higher concentrations you lose your ability to smell the gas even though it is still present.At high concentrations – your ability to smell the gas can be lost instantly.

Health Effects

Health effects vary with how long, and at what level, you are exposed. Asthmatics may be at greater risk. – irritation of eyes, nose, throat, or respiratory system; effects can be delayed. – more severe eye and respiratory effects, headache, dizziness, nausea, coughing, vomiting and difficulty breathing. – shock, convulsions, unable to breathe, coma, death; effects can be extremely rapid (within a few breaths).

Before Entering Areas with Possible Hydrogen Sulfide

The air needs to be tested for the presence and concentration of hydrogen sulfide by a qualified person using test equipment. This individual also determines if fire/explosion precautions are necessary.If gas is present, the space should be ventilated.If the gas cannot be removed, use appropriate respiratory protection and any other necessary personal protective equipment (PPE), rescue and communication equipment. Atmospheres containing high concentrations (greater than 100 ppm) are considered immediately dangerous to life and health (IDLH) and a selfcontained breathing apparatus (SCBA) is required.

Occupational

Safety and Health

AdministrationU.S. Department of Labor

http://www.osha.gov (800) 321-OSHA