Safe Use of Pressure Cylinders at Workplace

Pressure cylinders are cylinders having contents of various chemical composition under pressure in liquid or gaseous state. It is very important to provide due care and follow appropriate safety measures during storage, transportation, unloading, handling and use of pressure cylinders as they possess huge potential energy, which can lead to disasters on enormous scale, for both the lives and properties, if not managed properly.

Proper Use of Pressure Cylinders

Following safety precautions are required to prevent injuries caused by the improper use of pressure cylinders.

ALWAYS

- Secure cylinders with due care when in storage, transit, or use.

- Use regulators approved for the specific gas.

- Understand and have the knowledge of gases and its associated equipment which you would be using. Check supplier’s MSDS to decide the proper PPE and other special requirements for the gas being used.

- Use a separate control valve or a pressure-reducing regulator to discharge gas from a cylinder safely.

- Take proper care while moving cylinders, use a suitable hand truck or cart.

- Leak-test lines and equipment with an inert gas before using.

- Use pressure-relief devices and regulators when connecting cylinders to piping circuits with lower pressure service ratings.

- Keep practice of checking valves to prevent reverse flow into the cylinder.

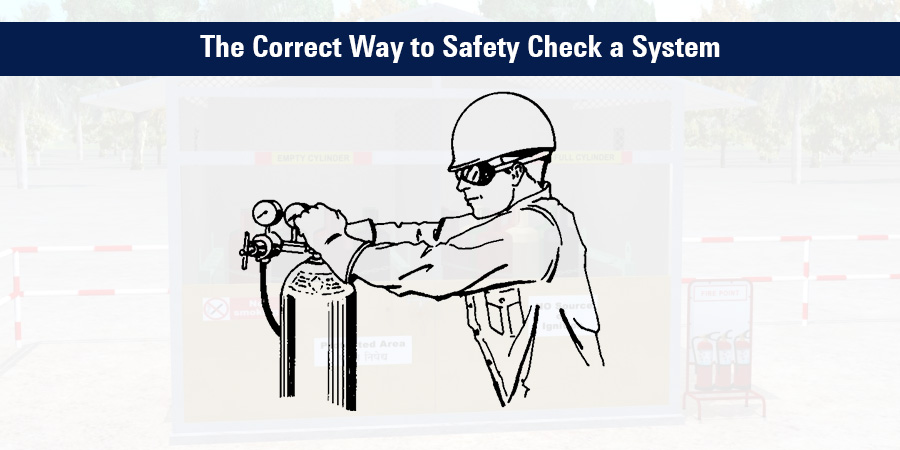

- When preparing to connect a cylinder, loosen the valve outlet seal slowly.

- Ensure to open cylinder valves slowly and carefully after connecting cylinder to the process.

- Avoid flames and sparks from coming in contact with cylinders.

- Use Teflon tape on systems for use in oxidizer service or oxygen.

- Suspend use and contact the supplier if a cylinder valve is difficult to operate.

NEVER

- Use oxygen as a substitute for compressed air.

- Allow cylinders to become part of an electrical circuit.

- Try to mix gases in a cylinder.

- Expose any part of a cylinder to temperatures exceeding 125°F (52°C).

- Introduce another product into a cylinder.

- Strike an arc on a cylinder.

- Identify cylinder color as a primary means to identify its contents.

- Choose a mechanical adapter to connect to the cylinder valve.

- Try to refill any (no) refillable cylinder after use of the original contents.

- Force cylinder valve connections that do not fit.

- Heat a cylinder to increase its withdrawal rate or its pressure unless using an approved method.

- Supplement any objects like screw, driver, wrench etc. into valve cap openings to remove a stuck cylinder cap.

- Modify service of equipment from the particular gas for which they are intended.

The above mentioned guidelines are given for those personnel/agency who are engaged in using pressure gas cylinder or their bank. However, the typical work situations prevailing at the work places must be given specific and technical considerations, to ensure safety.

Would you like to share your views? Send us your comments and suggestions.

In case, any query – Write to Us: info@ask-ehs.com or Contact +91 261 27 249 94.

No comments its an additional knowledge.