Professional resourcing for permit to work

One can agree to the fact that trained and skilled resources are vital to an organization – they do wonders in terms of productivity and efficiency. Trade-specific trainings in industries impart knowledge and skills that bring them the required ROIs while performing tasks.

To conduct those tasks, there are touchpoints in safety that emphasize on carrying out work with a safe approach. Compliance-wise, whether it be conducting a Job Hazard Analysis, risk assessment or permit to work – all stand crucial to work execution.

A work that is non-routine, has a potential to harm people, equipment or the environment, or needs alterations that can affect existing work conditions, require permits.

Demystifying Permit to work

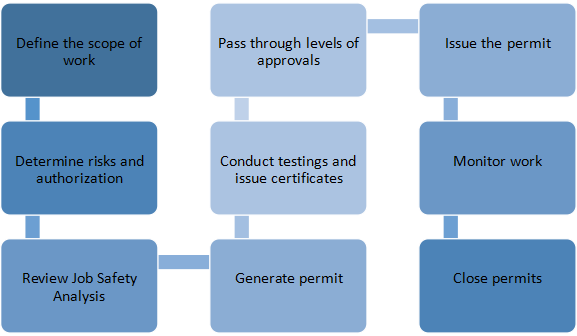

The diagram below explains the steps undertaken in permit to work –

In terms of compliance, permit process is made compulsory in all the industries. There are written protocols in place that explain how a permit process should be carried out. Digging deep into the Permit to work, we can recognize it as a documented process that lets employees know the essential precautions that have been undertaken, and where physical safe guards are in place, if necessary.

The solution vastly bridges the gap between machines, operators and safety engineers. It ensures effective accountability towards work procedures, communication throughout the job from planning to handover and restoration of normal working conditions. That ultimately prevent work conflicts with prior warning and anticipation.

But mostly, these systems are unsuccessful when it comes to execution.

Specialized resources that help in implementing PTW systems act as anchors while carrying out important processes. Where the scale and risk/hazard severity of the workspaces has magnified over the past years, these competent individuals make sure that the tasks are carried out in accordance with carefully considered conditions.

Personnel involved in the permit processes can reach out to these teams if they face issues at a large scale eg. Area and equipment isolations, shutdowns and outages. These actions further protect company assets (workforce and the plant) in every sense. Because their experience gives them the ability to provide insights in cases where accidents are caused by behavioural attitudes, lack of knowledge or simply, negligence.

The Piper Alpha oil rig incident in 1988, that lead to deaths of 167 workers was a major eye opener in relevance of permit to work system and its effective implementation.

The incident makes us realize that safety isn’t something that can be compromised – not even a bit. Eg. At a workplace, there can be contractor workers along with the employees, and ownership of decision-making processes are escalated to them as well, which makes it important for the industries to ensure the reach of adequate safety knowledge to the desired. Slight deviation in understandings can cause devastating effects – in case of Piper alpha, workers did not comply with LOTO procedures and Permit to work.

While these teams help in implementation, they make sure that no stakeholder is deprived of the necessary information. A constant reference is available for those undertaking high-risk errands, which, sort-of, releases the pressure of knowing everything from their minds.

Their qualms and uncertainties are responded without a delay, which can ultimately be a reason of increase in efficiency in their performance.

Image courtesy: U.S. Army Corps of Engineers Europe District, original photo can be found here photostream on Flickr – under title, Europe District conducts construction safety class in Turkey, accessed on 26-Feb-2020 – image resized.