Occupational health and safety – Shipbuilding industry

Shipbuilding industry is one of the oldest and heaviest production industries all over the world – production processes are variable, complicated and hazardous. Still, the industry continues to expand and brings benefits to the consumers. 90% of the world trade is carried by the shipping industry – it plays a central role in the import and export of goods on the scale necessary for the modern world.

But the construction of a ship is a highly complicated and technical process; it involves blending of many skilled trades. As the ship grows from the first steel plates, it becomes an ever-changing and complex environment with constantly changing subset of potential hazards. All of them not only require well-founded procedures for accomplishing the work, but also mechanisms for recognizing and dealing with the thousands of unplanned situations.

As the vessel grows, scaffolding or staging is added continuously to provide access to the hull (main body of the ship). This very construction has its own hazards, plus in addition, its completion exposes workers to increased risks as the height of the staging over the ground or water increases. Because as the hull begins to take form, the interior also takes shape (modern construction methods permit large subassemblies to be stacked on one another). Hence, enclosed and confined spaces are formed.

The hull can be a void that can contain ballasts, or have tanks, cargo holds, sophisticated combat control centres or simply sleeping compartments. Every case calls in for highly specialized workers working in close proximity – a typical scenario can have pipefitters brazing valves into position, electricians pulling wire cable and installing circuit boards, ship fitters positioning and welding deck plates, brush painters doing touch-up, crews of insulators or carpenters or a test crew verifying accuracy of systems.

All of these are everyday tasks that are further subject to schedule or engineering changes and weather. It is at this point that the labour-intensiveness of this industry becomes apparent.

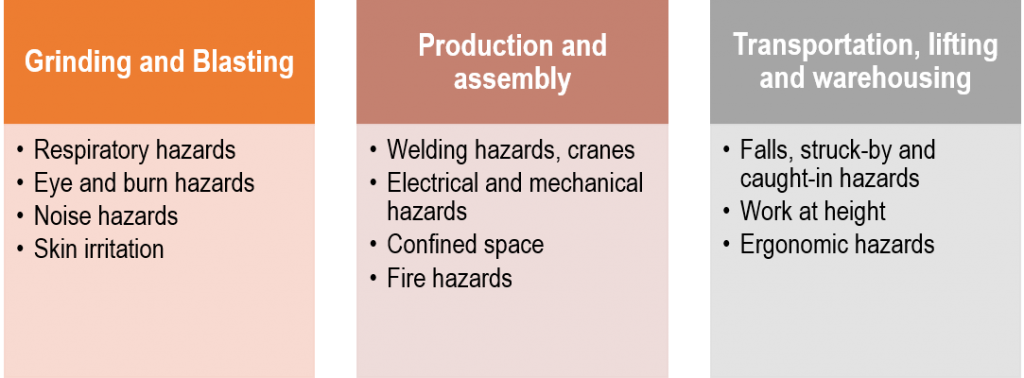

The industry encompasses shipyards and marine equipment manufacturing, maintenance and repair, comprises of risks such as work at heights, confined spaces and exposure to chemicals and metal fumes.

To avoid or reduce all of the above exposure to risks and hazards, health and safety must be well coordinated. The greatest achievements can be made when attention is turned towards the individual workers and focus is on eliminating behaviour that contributes significantly in accidents.

Workplace trainings, safety animation and E-learnings can emphasize, promote and influence safe behaviour at a workplace. All three have different learning mechanisms – where trainings are more direct and physically accommodate employees, animation and E-learnings benefit when good practices need to communicated in the shortest span. Animation offers a visually delightful experience – in one go, major processes, procedures, safe protocols and preventive measures of shipbuilding can be conveyed.

E-learnings summarize complex procedures with a mix of voiceovers, animation, tutorials – the gravity of this comprehensive industry can be better understood through them. Safety animation further allows the comprehensive display of complexity, scale of work and the several intermittent as well as necessary layers of safety barriers put in place to create a safer workplace.

All because health and safety of the personnel is of utmost importance – workplace practices and attitudes towards safe practices will prevent and reduce occupational hazards. Proper trainings, adequate use of PPE and safe protocols stand necessary. Surveillance, worker education and health awareness can prepare the workers for the worst.

Permit-to-work and Job hazard analysis carry significant weight – procedures can be adequate for most of the jobs that are carried on-board, but many tasks require extra care due to risks involved. Risks must be well assessed, and permits are also means of communication between those who carry out tasks, person responsible for safety and someone who could introduce a hazard when work is being carried out. Hence, they must be sincerely conducted wherever essential.

Enormous progress is visible in safety and health arena for the shipyard workers through improved equipment and construction methods, safer facilities and a highly-trained workforce. Shipbuilding industry must continue doing so, and as we move towards health and safety programs that involve workers more actively and consider their ideas, it raises worker awareness. This creates ownership of tasks within workers – with this, true success of health and safety can be realized.

Good job