How do you justify your investment in material handling training and technologies?

When we talk about Material handling techniques, we have agreed upon few processes for years – the movement, storage, and protection of products.

So does the industry’s primary subsegments – cranes, forklifts, and conveyor belts, as it has its own share of markets and capabilities.

And this segmentation and fragmentation has indeed helped the industries outshine in their respective areas, posing a relatively stable and health competition across.

Talking about the ‘4’ key dimensions of material handling

Movement, time, quantity, and space are the four dimensions of material handling.

How is material handling effective?

It improves efficiency by reducing the time it takes to move products from receiving to shipping, the length of time products remain in storage, the amount of product that fits into an allotted space, and the actual amount of available space.

This logistics process employs manual, automated, and semi-automated equipment.

Forklifts, trailers, pallets, hand trucks, tugger trains, and other equipment may be used.

And, if you work in industry, it makes more operational sense to consider materials handling logistics when starting, expanding, or moving your business, rather than later.

Material handling is essential in projects such as constructing or renovating plants and facilities, launching new products, improving workstations, and streamlining operations or reducing the use of forklifts.

The right material handling system meets a variety of needs—and having a system tailored to your specific, one-of-a-kind requirements can:

- Spend less money, time, and space

- Improve safety and capacity

- Reduce downtime and the amount of damaged or lost materials

- Enhance ergonomics, flexibility, and the working environment

Top 5 reasons for advancements in material handling

Here we top it off with few reasons so that it would be easier to associate yourselves with how these hi-tech innovations stand profitable to your operations in the long run!

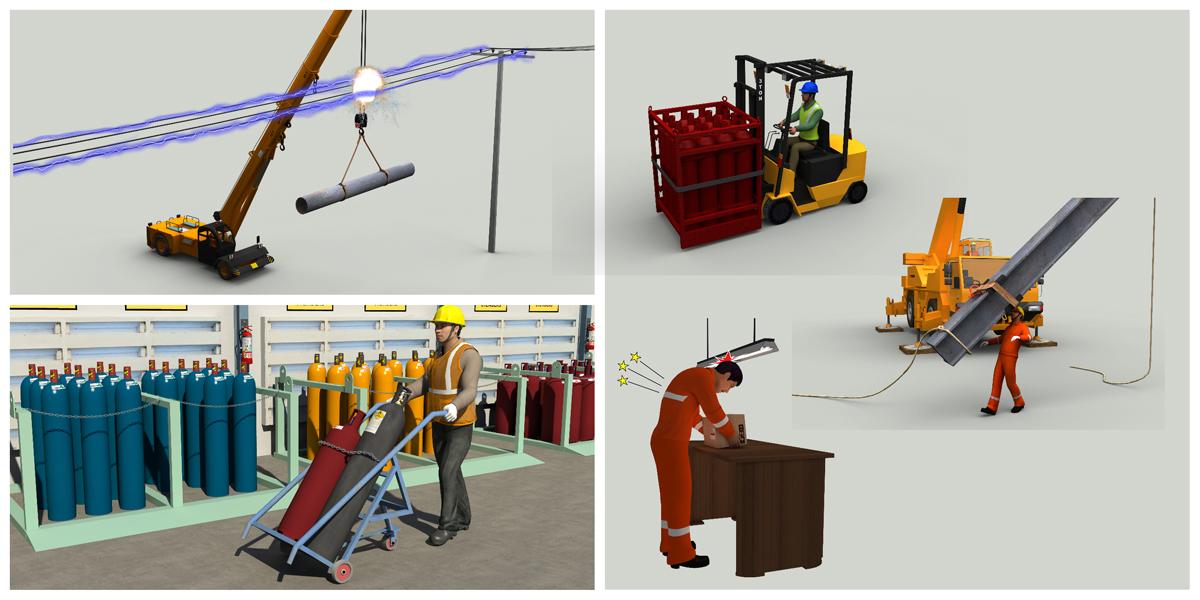

- Accident prevention: Having the proper lifting, moving, and storage equipment and machines reduces worker risk. In fact, improper material handling causes 21% of permanent disabilities and 25%+ of temporary disabilities.

- Improved efficiency: The right tools make it easier to organise products and materials, making it easier to track inventory and retrieve warehoused products.

- Reduced product damage: Improperly stored and moved products are more easily damaged, resulting in additional costs.

- Better plant layouts: Taking the time to plan and invest in proper plant layouts

- Improved customer service: When the right products are delivered quickly by a TRAINED WORKFORCE, it becomes the reason to save money and increases customer satisfaction.

But should we be considering several factors before implementing in our company?

- Can this product meet my requirements?

- Is the product worth the investment?

- How long will the product be in use?

- Examining emerging technologies. Will this product meet or exceed my expectations?

Goods-to-person systems, for example, arose in response to a need for high-density storage and equipment with a small footprint in order to free up floor space. Aside from maximizing space, today’s challenges include hiring and retaining qualified workers, as well as labour availability shortages, as well as meeting customer demands for faster response times. As a result, robotics and autonomous vehicle development are on the rise.

Let’s look at some of those emerging technology categories:

Robotic Picking – Fully Automated – This solution, described as the next generation of fast and accurate order fulfilment, is made up of a goods-to-person system, industrial robots, an AI vision system, and a takeaway conveyor utilising in-line automation solution

High Volume Robotic Loading – This one-of-a-kind automation solution automates docking stations in warehousing and manufacturing facilities, eliminating heavy and repetitive manual loading of completed box orders. It is a non-static solution that can drive to and from dock doors into truck trailers to execute precise case placement, making it more than just a lifting solution.

There are many more categories, but the main point is that all of these advancements make it easier to find a technology that truly meets your company’s needs.

When researching technologies, consider the following:

- How well-tested is the solution?

- Does it address critical issues and leave room for changing business objectives?

- Is there any software or technology that would need to be integrated?

- What kind of support infrastructure is available for this product?

How long will it be useful?

During so many options, within each aspect of material handling, you must be cautious about the equipment and technology you select. Some areas of concern are as follows:

Will the supplier still be in business in ten years or more? You would not want to enter a partnership with a company that is not financially secure, especially in these difficult economic times. A company with a solid foundation, excellent customer service, and a great product warranty helps to ensure some stability.

Is the product or system scalable? You want to ensure that the system can scale with your business. You don’t want to have to throw away any of it because you won’t be able to add to it later.

Can the technology support your future product portfolio? When a company has many products, some of them may become obsolete due to a lack of demand or the release of a newer version.

How long do you think your product will be relevant? Will new products replace old ones, and can the equipment or software handle the transition? Consider the possibilities for business acquisitions as well.

Investing in internal technological development to TRAIN AND TRAIN

Keeping up with changing technology has always been an issue in material handling.

Regardless of which path is best for them, industries absolutely need to cope up with the understandings of their employees, and effectively coach to pursue higher levels of automation.

As safety animation and eLearning providers, we shall assist you in attaining your ‘instructing and educational goals’! Primarily through improved cost efficiencies to freeing up resources for investments, enhanced digital technologies, and advanced analytics capabilities.

The puzzle pieces may be shifting, but the goals remain constant. The only way to succeed is to connect with customers quickly and accurately where they are and to meet their changing needs.

Very informative and effective post.

One of the best pros parts is its time savvy and safe as well

Content that is worth reading. Thank you for sharing this.