How about social distancing with our electrical equipment?

We’re sometimes a little too close for comfort.

COVID-19 has indeed taught us that a little social distance can provide a lot of protection. The same is true for your interactions with your electrical installations.

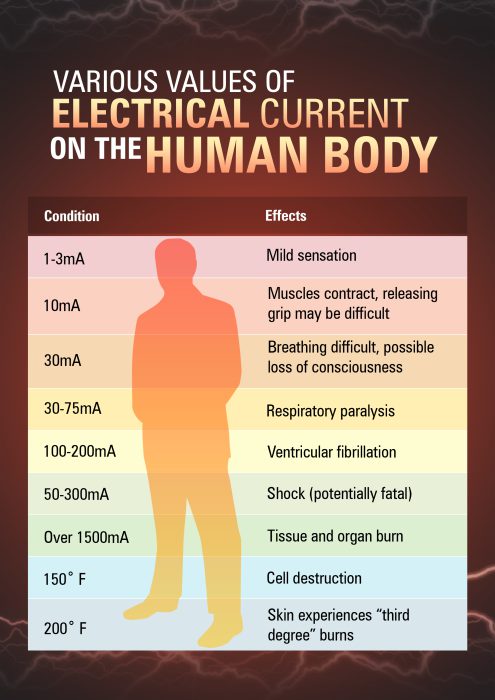

Talk about electrical equipment injuries, and we all know that it is a serious occupational health and safety concern.

Every year, thousands of electrical accidents occur, with 20 to 25 arc flash incidents occur every day. That are hazardous to workers’ health and costly to businesses.

According to OSHA, medical care for arc flash injuries can cost more than $1 million, in addition to costly equipment damage, power outages, and regulatory fines if safety protocols are not followed.

When you can interact with electrical equipment from a safe distance, you reduce safety risks such as an arc flash.

Converse with your electrical equipment, but not right next to it.

You don’t have to stand right next to your equipment to hear what it’s saying. You can monitor nearby equipment from a safer distance by using connected equipment and digital tools.

Apps and other digital tools collect real-time data about the health and performance of connected equipment from sensors. Apps use sensor data to provide remote operators with a complete, real-time visual picture of a substation, inside and out.

This technology allows field personnel to virtually inspect live nearby equipment from a comfortable safe distance, saving time during the equipment assessment process.

Get some work done

It is not only about monitoring, but also about command. Devices, for example, allows your field crews to put some distance between themselves and the equipment they need to work on.

This means that field technicians can operate live equipment from up to 10 meters/33 feet away using an app on their tablet or phone with no physical interaction.

Face masks are not unfamiliar to field crews, as working with live equipment necessitates extensive protective equipment, including shields. As a result, performing the same operations from a close range may become the new normal.

This reduces the risk of arc flash during circuit breaker racking, for example. These can happen when withdrawable components like circuit breakers and voltage transformers are inserted or removed from equipment, alternatively, “racked” in or out.

Instead, operators can rack in or out equipment while standing outside the arc-flash boundary by using an integrated remote racking system. Remote control also reduces worker exposure to hazards when performing operations such as repairing or monitoring equipment.

Consider a typical thermal inspection to see how digital tools and apps for nearby monitoring and control improve safety and efficiency.

Thanks to wireless thermal sensors that feed their measurements to an app on a field technician’s tablet, field crews can perform a thermal inspection on electrical distribution from a safer, closer distance.

The technician sees temperature data in real time, including unusual temperature rises that could lead to arc flash or fire hazards.

The technician can then use the same smartphone app to remotely operate the equipment from a nearby distance, all without requiring manual intervention or shutting down the substation.

While you’re at it, boost efficiency through training

Facility managers or third-party maintenance companies, for example, can use nearby training methods to increase efficiency, cost savings, value, and convenience.

Better maintenance, in general, keeps equipment healthier, which improves safety by reducing the need for equipment contact in the first place. It also improves operator safety by eliminating unplanned downtime, which can result in unsafe decision-making or safety hazards if operators fail to follow standard operating procedures, such as a rushed lockout-tagout procedure.

When field crews rely on safety training and animation to train their workforce, they are in the progress of achieving better health and safety performance for their workforce. Be it LOTO, or energized equipment, the knowledge should be handy for everyone to ‘return back to’, in cases of confusions.

Any question-and-answer session post a virtual training is a chance to gain remote visibility into their mental assets, allowing them to explore and question anything that they come across.

Thereby focusing on increasing the technical aspect and value of their workers.

Don’t be afraid to share

The tools that enable nearby monitoring and control do not exist in isolation. Neither does the information that feeds them.

They are part of an architecture and a suite of digital tools that can span a company’s operations across the entire lifecycle to meet their specific needs, whether that is improved collaboration, increased productivity, safer operations, or improved equipment health.

Social distancing with electrical equipment is must

But it goes much deeper than that. Learning tools can be used to not only increase the safety between operators and equipment, but also to reduce human error, which is one of the leading causes of arc flash.