Evaluating OHS management systems and software in place

If asked to the corporate safety professionals about the reasons to stay committed to prevent serious injuries and deaths amongst workers, most of them would definitely respond that they care for their employees and do not want to see anyone hurt. Plus, they would admit that “safety pays” when it comes to cost reduction and organization’s reputation.

But many-a-times, such rationales hardly lead to any significant changes in the workplace safety – plus underneath, a safety professional’s implicit and unfounded belief that there’s a tradeoff between profits and expenditures necessary to keep the workplace safe, stays.

As safety at a worksite deteriorates, product quality and plant performances that are based on internal and external measures suffers.

And for the same, arrived OHS management systems in place. The key reason being, to improve the organizational performance. As the improvement leads to perceiving management system a success.

To judge an OHS management system, three things remain key –

- A common understanding of what improved performance means

- Metrics or performance indicators to measure performance

- Sufficient quality data to determine whether selected metrics have been achieved

Rethinking your OHS management systems in place

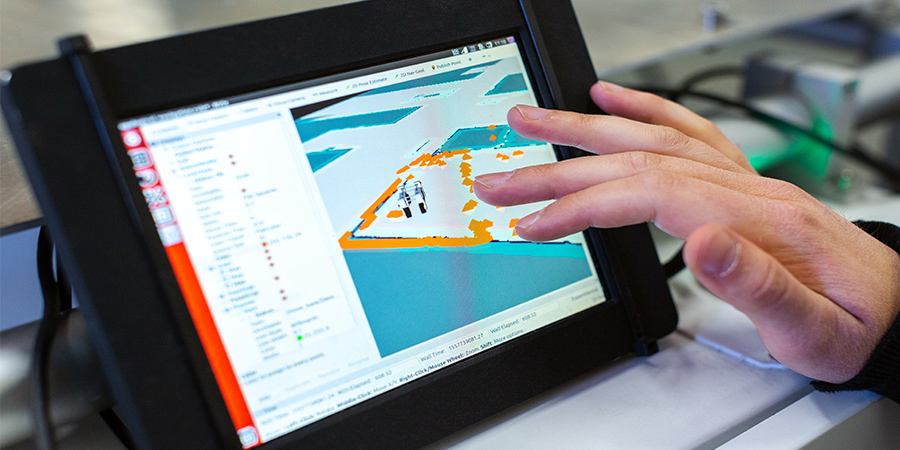

An EHS software proves to have a major role – from communication to documentation and training, right software tools can facilitate all the important processes of a safety management system.

Also while evaluating an industrial performance, there are two intended outcomes – reactive and proactive. Within 2 proactive outcomes – one is providing a safe place of work, and second is the prevention of injury and ill-health to the workers.

ASK-EHS safety software focusses on delivering appropriate performance indicators, as every management system emphasizes on a process focus and the outcome focus. When an industry decides on the purpose for which a particular performance indicator is to be used and by whom, their further focus remains to exclusively focus on outcome metrics.

It helps the safety professionals to calculate and compare lost workdays and injury statistics. They use these statistics for their sustainability reporting and measuring managerial performance. Which further can be used to determine audit and inspection frequency and to target OHS improvement initiatives.

Nothing should take precedence over safety

Collecting and analyzing data as a part of the monitoring activity often is expensive and time-consuming – three concepts that are important to consider are validation, verification and calibration.

To get a complete picture of all safety program activities, safety software equips the employees to quickly access the information that they need and report issues.

At its core, it starts with hazard identification that includes safety policy, plans, objective setting, safety training schedules, meeting schedules, any reporting procedures, committee and management structures, responsibility assignment and anything else that applies.

If you are still unsure of how a safety software benefits, recall each aspect of working at a construction site (for e.g.) – moving to and fro means a lot of paperwork. Even the creation and implementation of safety management systems is made much easier – most importantly, it cuts down the paperwork and tasks such as incident reporting, filing, audits and more are simplified.

While evaluating an OHS management system, one can deduce the fact that it needs to reduce the risk of siloed information and oversights due to lack of shared knowledge.

Which further contributes to a strong safety culture when everybody remains on the same page. In a software, everything is put together in one system and there remains more transparency, and workers are clear in the fact about the procedures, and the information that they need.

With many moving parts, ASK-EHS safety software strives to simplify your industrial processes and help you obtain a better oversight of the whole picture.

Get in touch with our team if you are convinced about meeting your site safety requirements and goals.