Digital Permit to work for FPSO operations

One can understand an FPSO unit in this fashion – it is basically a ship (floating vessel) used by the offshore oil and gas industry for the production and processing of hydrocarbons, and for oil storage. On observing, we can picture hundreds of people confined out on sea on huge, floating refineries which store barrels of oil under their feet.

An FPSO project, before its final hookup, consists of mechanical completion, pre-commissioning and commissioning – it’s planning remains critical to schedule adherence, successful installation and ultimate handoff for the operation of a facility.

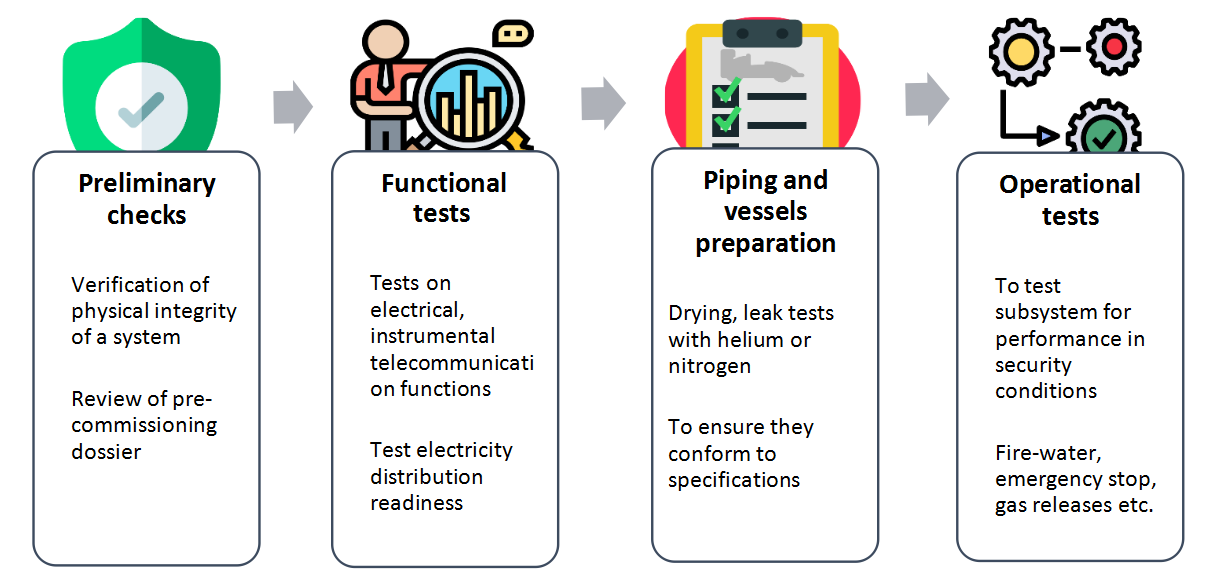

On an average, an FPSO consists of 95 to 105 systems, where certain ‘commissioning activities’ are mandatory to be carried out – functional (systems and sub-systems) and equipment breakdown for each project is necessary.

Above figure can explain the gravity of activities undertaking in an FPSO. Here, the inconvenience is that the project is divided into too many tasks (can’t help it as every bit is important). Many times, people or teams processing these different tests are not the same, and at times tests present some difficulties, workflow inefficiencies and redundancies. So ultimately, the time gained by sub-dividing of tasks might easily be lost into retesting.

One is the hazardous nature of this industry and second is the involvement of simultaneous operations (SIMOPS); a systematic approach towards managing both can decrease the magnitude of the risks.

The provision of Permit to Work is therefore, fundamental to offshore activities – it supplements all the above construction and commissioning activities. Along with blanket isolations for electrical, mechanical and instrumentation, specialized permits suit the entire project commissioning lifecycle – load tests for gas turbines, gas compression testing with nitrogen gas, FPSO turret and drilling rig commissioning.

Tracking and tracing data is obligatory in such cases – paper permits lack these as in such cases, it becomes difficult to locate archive information and record critical overlapping data. Eg. In the permit process, especially while performing isolation of various tags (that can have more than 20 characters), entries are subject to manual error.

For each activity, there are engineering (reference) documents needed for the representation of the installation. These are isometric diagrams, Process and Instrumentation diagrams (PIDs), Process and Flow Diagrams, Single-line Diagrams etc. In permit processes, when a central repository for document retrieval and referencing is enabled, permit escalations consume little to no time. That makes the correct project information readily visible to the concerned industry personnel.

Digitized Permit to work – an efficient and compliant approach

A paper-based approach for permits is ineffective – a digitized solution can anticipate deviations in processes and help streamline activities.

Offshore industries no longer work with a single contractor, and in order to minimize risks for investment, they subcontract projects to multiple contractors. Interfaces with them are frequent – at times, there might be chances of conflicts between shifts and failure in adequate communication. So safe handover of tasks to contractors remain crucial.

A comprehensive permit to work system to automate routine tasks can ease the process of safeguarding contractors and workers – site activities are streamlined, clear oversight of work and efficient execution is enabled.

A digitized PTW is capable to suit the entire project lifecycle; a right technology partner helps and allows seamless transition of workflows and where necessary, facilitates integration. All of the above challenges can be mitigated using a right PTW software, where it can be designed to the highest levels of usability.

By tightly integrating a digitized PTW with planning, workforce and equipment, capacities can be coordinated on a deeper level than before, thus increasing efficiency, traceability and accuracy tangibly.

I subscribed to the use of digital ptw because it will go a long way to faster the operations in every giving time. therefore, i will like to get the software if is available.,

Hello Britokany,

Yes, Digital PTW software is available. You can review our web-page: http://bit.ly/37whfQU

or

You can send your requirements on: info@ask-ehs.com

Look forward to hearing from you…

Dipal H. Ejardar