ASK-EHS’ MSDS Module – Maintain All Chemical MSDS Records Efficiently

What is the first thing we do when we buy new equipment?

We go through the manual and try to understand the dos and don’ts of using the equipment. But despite using the equipment regularly, we still keep the manual preserved to know what to do if the equipment faces any issues. Also, if anyone else is given to use the equipment, we ensure to pass on the manual.

These technical manuals still exist today, but customers know they can be found digitally on the company’s website, so do not preserve them thoroughly. This digital evolution is a good thing for the environment and the customers. When customers can find answers easily to their queries, they use the equipment properly and thus avoid any mishappenings related to the same.

Now this situation is amplified multiple times when it concerns the chemical industry. The chemical sector has to maintain Material Safety Data Sheets, aka MSDS. These documents provide complete knowledge of the substances they are working with or handling.

So let us explore MSDS in a detailed way and understand how their digital evolution plays a vital role in escalating safety.

Material Safety Data Sheets (MSDS): An Overview

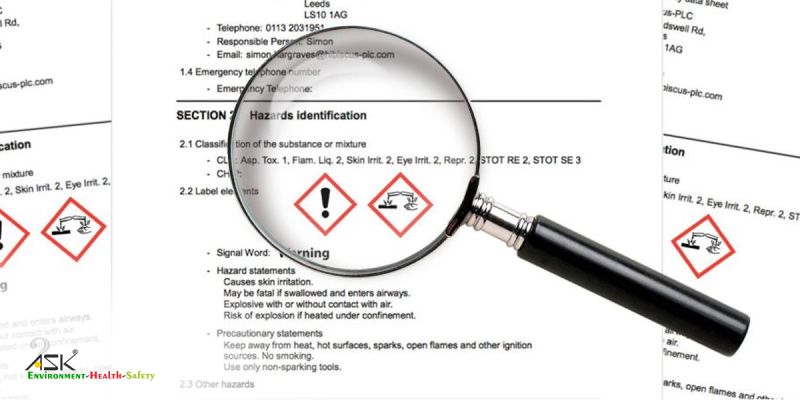

MSDS are reference sheets that contain everything one needs to know about a particular chemical. These sheets are universally defined and include details such as the substances’

- Physical and chemical properties

- Uses

- Effects

- Regulations

- Protection against effects

- Hazards

- Handling

- Storage

- Routes of exposure

- Precautionary and control measures

- Emergency and first-aid procedures

The MSDS has a fixed format and generally contains 16 sections wherein the above, and more necessary information is printed. The data is presented under proper headings and subheadings. These sheets are required to be up-to-date and complete. They need to have the manufacturer’s information and details about the chemicals’ existence in the literature.

Initially, it was a tedious task to maintain MSDS and update them. But storage and maintenance of these sheets is a crucial safety regulation defined by OSHA and other safety regulations. Therefore, what needed to be done had to be done in the best way possible.

Then we stepped into the age of digitalization. The MSDS was stored in CD-ROMS, pen drives, and other physical hardware from paperwork bounties. Further, these physical drivers were replaced by servers and clouds. But now, an ultimate solution has come to stay for a long time. And not just because it is easy to use but because it is convenient and reliable.

Let us read through to learn about the fantastic MSDS module.

ASK-EHS’ MSDS Module

We understand that violations related to MSDS happen regularly and lead to dangerous results. Therefore, there should be a standardized and systematic way to maintain and access these essential sheets.

ASK EHS has developed an SDS module that can help to maintain MSDS records of all the hazardous substances and chemicals used within the organization.

This software allows

- Users to keep centralized records of manufacturers and suppliers of hazardous substances and chemicals along with their MSDS.

- Uploading of file attachments that can provide details like:

- Chemical Product and Company Identification

- Hazards Identification

- Fire and Explosion Data

- Handling and Storage

- Exposure Controls/ Personal Protection

- Tracking of product details according to product code.

If your business handles hazardous chemicals, you must have an SDS module integrated into your safety system. This integration ensures that your employees have ready access to MSDS. Thus, employees follow best practices while handling chemicals as they know help is readily and quickly available. These digital sheets also serve as a quick response system if workplace accidents occur.

Benefits of ASK-EHS’ MSDS Module

Here are the six best reasons why you should integrate ASK EHS’s MSDS module immediately into your safety system.

You have a complete, comprehensive, and updated list of chemicals.

This digital system effortlessly maintains SDS sheets for every hazardous substance used at your workplace. These sheets are easily accessible; if any SDS is missing, you can immediately contact the manufacturer and update the system. The system ensures that the sheets are maintained, accessed, and updated seamlessly.

SDSs are Readily Accessible

Employees can readily access SDSs irrespective of their shift hours. They do not need to bother any managers or peers but have complete knowledge of the substance they are handling at their fingertips.

The Specifics Are Easily Determined

If the same chemical is sourced from different manufacturers or suppliers, their details must be attached appropriately. The specific information about the chemical compositions, when it was bought, and when to use can be easily availed by the team member through the SDS module. They have to search for a particular query and get information within a few minutes.

Amplified Safety Culture

When employees can easily access the data sheets, it shows that the organization cares about their safety and has invested in it. This robust system keeps MSDSs secure and promotes best practices to avoid accidents and incidents.

Increased Visibility

The MSDS module offers greater visibility for the managers. They can effectively track safety compliances. They have information about which sheets are being accessed on the site, whether employees are accessing them correctly, and is the SDS sheet updated regularly. The digital system gives managers an in-depth understanding of how these documents are used. This results in robust, actionable insights for safety and compliance.

Avoid Fines and Non-Compliances

Maintaining updated MSDS sheets is a regulatory clause for safety by OSHA and other local laws. Therefore, if any of the sheets fail to meet the standards during auditing, the business can face heavy fines, penalties, and other legal actions. Consequently, this software allows you to be ready for every inspection while ensuring your MSDS sheets are in place and updated.

An Overall Safety Approach

Digital tools for safety and MSDS sheets have proved revolutionary for organizations. And when it comes to the chemical sector, MSDS must be treated crucially.

And not only SDS sheets but digitalizing the organization’s overall safety system is the need of the hour. This 360-degree solution includes complete and customized solutions for hazard management, incident reporting, job safety analysis, inspections, audits, and more. The cloud-based safety management software makes it easier to be safe and compliant.