3 Key benefits to gain from Scaffolding Operations Management Software

Scaffolding operations are a highly complex, hazardous and labour intensive activities taking place around the world. Larger work sites requiring scaffolds in high quantities find it tough to keep up with the operational challenges. Most organizations put in huge efforts in making it work efficiently. The usual approach is to use a paper based request & approval process, manual preparation of reports, managing data / records in spreadsheets and / or other similar documentation tools.

According to OSHA, nearly 65% of all construction workers work on scaffolds regularly. At the same time, construction sites are permanently tough environments with the rapid movement of workers and heavy equipment, material transfers and conversions, changing landscapes etc. Automation, wherever possible, must be encouraged considering the volume and magnitude of work.

Scaffolding operations entail several processes, mandatory checks / inspections, tagging, engineering controls, safety precautions and protocols, schedules and a myriad of other activities. A big percentage of these activities happen on the field. Using custom software, organizations can look to automate many of the essential processes and data collection activities. Once it is digitally enabled, many of the cumbersome tasks (e.g. preparing reports) can be completed by the software, giving enough freedom to the operations team to focus on other more critical activities.

While there are several benefits that organizations can experience through software, let’s take a look at 3 Key Benefits that are likely to provide huge ROIs;

- Measuring productivity

- Optimum utilization of material

- Savings in operational expenses

- Measuring Productivity

Scaffolding operations require timely and diligent execution considering the nature of work that is needed. But how do you measure productivity? Apart from its complex (and diverse) nature, authorities need to manage multiple scaffold jobs in large project venues. One key component to the entire operations remains allocation of appropriate resources (workmen) to a particular job/assignment.

Using software, authorities are able to capture actual time and efforts that go into any particular assignment. By collecting sizeable data, decision makers can compare performance of different contractors. Contractors can find weak link / weak team within their organization as well. These useful bits of information help in defining the strategies for contractual terms, competency improvement and during review of their efforts.

- Optimum Utilization of Material

Another critical activity is the accurate estimation and allocation of material for any particular job / assignment. The software provides a reference to historicalrecords with actual material utilized that can be used as strong reference during material estimation for the particular job. The software also helps authorities keep accurate records of dismantling jobs. This way, material can be planned for future requests and in many cases, transferred straight away from the dismantled job to designated new scaffold job site, thereby, leveraging the value. Further to this, software will also keep records of store inventories (at store, staging areas, material in-use) and helps to ensure no extra material is procured other than what is required.

- Savings in Operational Costs

A conventional scaffold cycle would include scaffold requests, permits, multiple approval points/agencies, certificates, maintaining of records and multiple communication with and between authorities/agencies at different levels. A good example of a digital advantage is that one can capture the image of the site where scaffold is requested.

The requester can also annotate (sketch) on the place where s/he requests for the scaffold along with annotation of nearby hazards, thereby, reducing a lot of the physical time and effort of approving agencies. The approving authorities on their part are able to gauge the criticalities of the requested job and take important decisions (whether physical inspection is required or not). This saves a huge amount of their time and effort if we consider hundreds of scaffold requests being processed at a day.

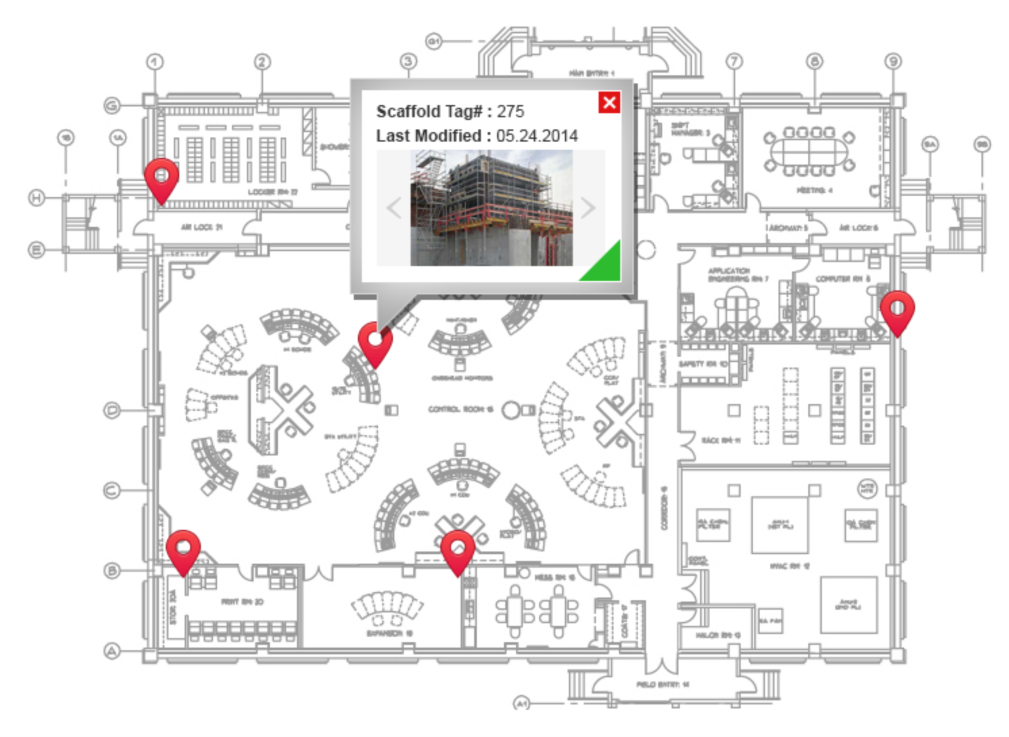

Bonus: The Area Map feature is especially useful for authorities and has proven to attain huge amounts of ROI for organizations. One is able to;

- View various scaffold access points instantly

- Get scaffold tag status in real-time

- Check and review up-time of scaffolds

- Check for any modifications that can be done to existing scaffoldings

- Get status of scaffold builds (mantle and dismantle)

The Cost-to-benefit ratio of Scaffolding Management Software is a huge one. Some patrons have reported savings of millions of dollars* in the very first year of using the software. Learn more about the software here: Scaffolding Management Software

What are the challenges that custom software for scaffolding operations management would be able to resolve for you? Let us know in the comments box.

(*Internal survey of ASK EHS customers done to measure Scaffolding Operations Management Software ROI)

A good example of a digital advantage is that one can capture the image of the site where scaffold is requested.